12 Ton Hydraulic Press: A Comprehensive Guide

Are you looking to invest in a hydraulic press for your workshop or industrial setting? The 12 ton hydraulic press is a popular choice due to its versatility and power. In this detailed guide, we will explore the various aspects of the 12 ton hydraulic press, including its features, benefits, applications, and maintenance tips.

Understanding the Basics

The 12 ton hydraulic press is a type of mechanical press that uses hydraulic fluid to generate force. It is designed to apply a compressive force of 12 tons, making it suitable for a wide range of applications, from metalworking to plastic molding.

Here’s a quick overview of the key components of a 12 ton hydraulic press:

- Hydraulic Cylinder: This is the main component that generates the compressive force. It consists of a piston, cylinder, and hydraulic fluid.

- Hydraulic Pump: The pump circulates the hydraulic fluid, providing the pressure needed to operate the press.

- Valves: These control the flow of hydraulic fluid, ensuring that the press operates smoothly and safely.

- Control Panel: This allows you to adjust the pressure, speed, and other settings of the press.

Features of the 12 Ton Hydraulic Press

When choosing a 12 ton hydraulic press, there are several features to consider:

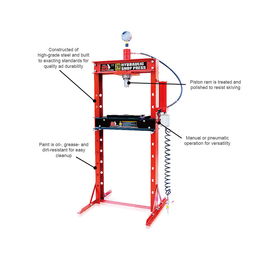

- Frame Material: Look for a press with a sturdy frame made of high-quality steel. This ensures durability and longevity.

- Table Size: The table size should be sufficient to accommodate your workpieces. Consider both the length and width of the table.

- Stroke Length: The stroke length determines how far the press can travel. Choose a stroke length that suits your specific needs.

- Speed: The press speed should be adjustable to accommodate different types of workpieces and operations.

- Control System: A modern control system allows for precise control of the press, improving safety and efficiency.

Benefits of Using a 12 Ton Hydraulic Press

There are several benefits to using a 12 ton hydraulic press:

- Increased Productivity: The press can handle a wide range of tasks, from metal stamping to plastic molding, reducing the need for multiple machines.

- Improved Safety: The press is designed to operate safely, with features such as emergency stop buttons and overload protection.

- Cost-Effective: While the initial investment may be significant, the press can save money in the long run by reducing the need for manual labor and minimizing downtime.

- Customization: Many manufacturers offer customization options, allowing you to tailor the press to your specific needs.

Applications of the 12 Ton Hydraulic Press

The 12 ton hydraulic press is suitable for a wide range of applications, including:

- Sheet Metal Fabrication: The press can be used for bending, stamping, and forming sheet metal.

- Plastic Molding: It is ideal for molding plastic parts, such as automotive components and consumer goods.

- Forging: The press can be used for forging metal parts, such as gears and shafts.

- Pressing and Compacting: The press can be used for pressing and compacting materials, such as powders and granules.

Maintenance Tips for Your 12 Ton Hydraulic Press

Proper maintenance is essential to ensure the longevity and performance of your 12 ton hydraulic press. Here are some tips:

- Regular Inspection: Check the press for any signs of wear or damage, such as leaks or loose bolts.

- Hydraulic Fluid: Replace the hydraulic fluid at regular intervals, as it can become contaminated over time.

- Seals and Gaskets: Inspect and replace seals and gaskets as needed to prevent leaks.

- Control Panel: Keep the control panel clean and free of dust to ensure proper operation.

By