500 Ton Crane: A Comprehensive Guide

When it comes to heavy lifting, the 500 ton crane is a marvel of engineering and precision. This powerful machine is designed to handle some of the most demanding lifting tasks in various industries. In this article, we will delve into the details of the 500 ton crane, exploring its specifications, applications, and the technology behind it.

Design and Specifications

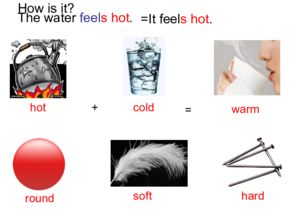

The 500 ton crane is a massive piece of equipment, typically featuring a lifting capacity of 500 tons. Its design is robust and durable, ensuring it can withstand the rigors of heavy lifting. Here are some key specifications to consider:

| Parameter | Value |

|---|---|

| Lifting Capacity | 500 tons |

| Maximum Boom Length | Up to 200 feet |

| Maximum Lifting Height | Up to 300 feet |

| Counterweight | Up to 100 tons |

| Engine Power | Up to 600 horsepower |

These specifications make the 500 ton crane suitable for a wide range of applications, including construction, shipyards, and mining operations.

Applications

The 500 ton crane is a versatile piece of equipment that finds applications in various industries. Here are some of the most common uses:

-

Construction: The crane is ideal for lifting heavy materials, such as steel beams, concrete slabs, and machinery, during the construction of skyscrapers, bridges, and other large-scale projects.

-

Shipyards: The crane is used for lifting and installing heavy ship components, such as propellers, engines, and hull sections.

-

Mining: The crane is employed for moving large mining equipment, such as draglines and crushers, as well as for handling ore and other materials.

-

Energy Sector: The crane is used for lifting heavy equipment during the construction and maintenance of power plants, wind turbines, and other energy infrastructure.

Technology and Safety Features

The 500 ton crane is equipped with advanced technology and safety features to ensure efficient and secure operation. Here are some of the key features:

-

Hydraulic System: The crane features a powerful hydraulic system that provides smooth and precise control over lifting operations.

-

Load Sensing: The crane is equipped with load sensing technology, which allows operators to monitor the load in real-time and adjust the lifting speed accordingly.

-

Anti-Collision System: The crane is equipped with an anti-collision system that detects nearby obstacles and automatically adjusts the lifting path to avoid collisions.

-

Emergency Stop: The crane is equipped with an emergency stop button that can be activated in case of an emergency to immediately halt the lifting operation.

Operator Training and Certification

Operating a 500 ton crane requires specialized training and certification. Operators must undergo rigorous training to ensure they are proficient in handling the equipment safely and efficiently. Here are some key points to consider:

-

Training Programs: Operators must complete a comprehensive training program that covers the crane’s design, operation, maintenance, and safety procedures.

-

Certification: Upon successful completion of the training program, operators must obtain a certification that demonstrates their competence in operating the crane.

-

Continuous Training: Operators must undergo regular training and re-certification to maintain their skills and knowledge.

Conclusion

The 500 ton crane is a powerful and versatile piece of equipment that plays a crucial role in various industries. Its robust design, advanced technology, and safety features make it an ideal choice for heavy lifting tasks. By investing in operator training and certification, companies can ensure the safe and efficient operation of these cranes.