17 Ton Shackles: A Comprehensive Guide

When it comes to heavy-duty lifting and securing, the 17 ton shackle is a piece of equipment that stands out for its robustness and reliability. Whether you’re working in construction, mining, or any other industry that requires the lifting of heavy loads, understanding the intricacies of a 17 ton shackle is crucial. In this article, we delve into the details of this powerful lifting device, exploring its design, specifications, applications, and maintenance.

Design and Construction

The 17 ton shackle is designed to withstand immense forces, making it a favorite among professionals in the heavy-duty lifting industry. Made from high-quality steel, these shackles are built to last, ensuring that they can handle the rigors of daily use. The shackle features a forged body, which provides exceptional strength and durability. The body is typically made from materials such as alloy steel or manganese steel, which are known for their high tensile strength and resistance to wear and tear.

One of the key components of the 17 ton shackle is the pin. The pin is designed to be removable, allowing for easy attachment and detachment of the shackle from lifting chains or cables. The pin is usually made from the same high-quality steel as the body, ensuring that it can withstand the forces exerted during lifting operations. The pin is also equipped with a locking mechanism, such as a cotter pin or a safety latch, to prevent accidental release of the shackle during use.

Specifications

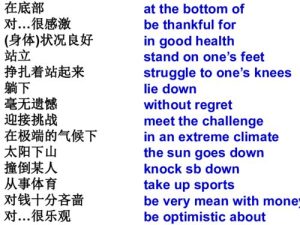

When selecting a 17 ton shackle, it’s important to consider its specifications to ensure that it meets the requirements of your lifting application. The following table provides a breakdown of some common specifications for 17 ton shackles:

| Specification | Description |

|---|---|

| Working Load Limit (WLL) | The maximum safe load that the shackle can support without failure. |

| Breaking Strength | The force required to break the shackle under laboratory conditions. |

| Material | The type of steel used in the construction of the shackle. |

| Finish | The surface treatment applied to the shackle to enhance corrosion resistance. |

It’s important to note that the specifications of a 17 ton shackle can vary depending on the manufacturer and the specific design of the shackle. Always consult the manufacturer’s specifications or a qualified professional to ensure that the shackle you choose is suitable for your application.

Applications

17 ton shackles are widely used in various industries due to their strength and reliability. Some common applications include:

- Construction: Used for lifting heavy equipment, materials, and structures.

- Marine: Employed in shipbuilding, cargo handling, and offshore operations.

- Manufacturing: Utilized in the assembly and transportation of heavy machinery.

- Transportation: Used in the loading and securing of heavy cargo on trucks and trains.

These shackles are designed to handle the demands of these industries, ensuring that heavy loads are safely lifted and secured.

Maintenance and Safety

Proper maintenance and safety practices are essential when working with 17 ton shackles. Here are some key points to consider:

- Regular Inspection: Inspect the shackle for any signs of wear, damage, or corrosion before each use. Pay close attention to the pin, body, and locking mechanism.

- Load Calculation: Always ensure that the load being lifted does not exceed the shackle’s working load limit (WLL). Overloading can lead to failure and serious injury.

- Proper Handling: Use appropriate lifting equipment and techniques when handling 17 ton shackles. Avoid dropping or throwing the shackle, as this can cause damage.

- Training: Ensure that all personnel who work with 17 ton shackles are properly trained in their safe use and maintenance.

By following these guidelines, you can help ensure the safe and efficient operation of your 17 ton shackles.

In conclusion, the 17 ton shackle is