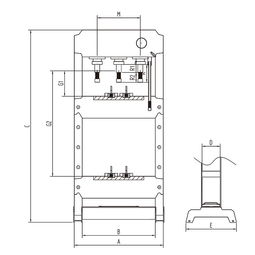

20 Ton Press Parts Diagram: A Comprehensive Guide

Understanding the components of a 20 ton press is crucial for anyone involved in manufacturing or maintenance. This guide will delve into the various parts of a 20 ton press, their functions, and how they work together to ensure efficient and safe operation.

Frame and Base

The frame and base of a 20 ton press are the foundation upon which the entire machine is built. The frame is typically made of heavy-duty steel and provides structural support. The base, on the other hand, is designed to distribute the weight of the press evenly, ensuring stability during operation.

Power Unit

The power unit is the heart of the 20 ton press, providing the necessary energy to operate the machine. It can be either electric or hydraulic, depending on the specific model. Electric presses use an electric motor to power the press, while hydraulic presses use a hydraulic pump and motor to generate the required force.

Work Table

The work table is where the materials to be pressed are placed. It is designed to be sturdy and flat to ensure that the materials are properly aligned and pressed. The work table can be adjustable in height to accommodate different thicknesses of materials.

Slide and Ram

The slide and ram are the moving parts of the press. The slide is the vertical movement of the press, while the ram is the horizontal movement. The ram is connected to the slide and moves back and forth, applying pressure to the materials on the work table.

Clamping Mechanism

The clamping mechanism is responsible for holding the materials in place during the pressing process. It ensures that the materials do not move or shift while the press is in operation. The clamping mechanism can be manual or automatic, depending on the model of the press.

Control Panel

The control panel is the interface between the operator and the press. It allows the operator to control the various functions of the press, such as the speed of the slide, the pressure applied, and the cycle time. The control panel can be simple or complex, depending on the features of the press.

Safety Features

Safety is a top priority in the design of a 20 ton press. Various safety features are incorporated to prevent accidents and ensure the well-being of the operator. These include emergency stop buttons, safety guards, and overload protection.

Table of Common 20 Ton Press Parts

| Part | Description |

|---|---|

| Frame | Provides structural support for the press |

| Base | Distributes weight evenly and ensures stability |

| Power Unit | Generates the necessary energy to operate the press |

| Work Table | Supports materials during the pressing process |

| Slide | Vertical movement of the press |

| Ram | Horizontal movement, applies pressure to materials |

| Clamping Mechanism | Holds materials in place during operation |

| Control Panel | Interface for controlling press functions |

| Safety Features | Prevent accidents and ensure operator safety |

Understanding the various parts of a 20 ton press is essential for anyone working with this type of machinery. By familiarizing yourself with the components and their functions, you can ensure safe and efficient operation of the press. Whether you are a manufacturer, maintenance technician, or operator, this guide will help you navigate the complexities of a 20 ton press.