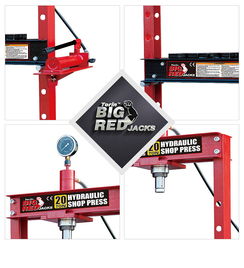

40 Ton Shop Press Parts: A Comprehensive Guide

Are you looking to enhance your workshop with a reliable and versatile 40 ton shop press? If so, you’ve come to the right place. In this detailed guide, we’ll delve into the various parts that make up a 40 ton shop press, their functions, and how they contribute to the overall performance of the machine. Whether you’re a DIY enthusiast or a professional mechanic, understanding the components of your shop press is crucial for maintenance, repairs, and optimal usage.

Frame and Base

The frame and base of a 40 ton shop press are its foundation. They provide stability and support for the entire machine. The frame is typically made of heavy-duty steel, ensuring durability and longevity. The base, on the other hand, is designed to distribute the weight evenly, preventing any potential damage to the floor or foundation.

Hydraulic System

The hydraulic system is the heart of a 40 ton shop press. It converts mechanical energy into hydraulic pressure, which is then used to lift and lower the press ram. This system consists of several key components:

-

Pump: The pump is responsible for circulating hydraulic fluid through the system. It creates the pressure required to operate the press.

-

Reservoir: The reservoir stores hydraulic fluid and helps maintain the pressure within the system. It also serves as a heat sink, dissipating excess heat generated during operation.

-

Valves: Valves control the flow of hydraulic fluid, ensuring that the press operates smoothly and efficiently. Common types of valves include directional valves, pressure relief valves, and check valves.

-

Hoses and Fittings: These components connect the various parts of the hydraulic system, allowing fluid to flow freely. It’s important to use high-quality hoses and fittings to prevent leaks and ensure optimal performance.

Press Ram

The press ram is the part of the shop press that moves up and down. It is designed to exert a significant amount of force, allowing you to perform various tasks such as bending, forming, and stamping metal. The ram is typically made of high-strength steel, ensuring it can withstand the pressure and weight of the materials being worked on.

Die Blocks and Hold-Downs

Die blocks and hold-downs are essential for securing the materials being worked on. Die blocks are placed on the press bed and are used to hold the dies in place. Hold-downs, on the other hand, are used to secure the materials being pressed. They come in various sizes and shapes, allowing you to work with different types of materials and dies.

Control Panel

The control panel is the interface between the operator and the shop press. It allows you to adjust the pressure, speed, and other settings of the machine. Modern control panels often feature digital displays and programmable functions, making it easier to operate and maintain the press.

Workbench and Bed

The workbench and bed are the surfaces on which you’ll perform your metalworking tasks. The workbench is typically made of sturdy material, such as steel or cast iron, and is designed to withstand the weight and pressure of the materials being worked on. The bed is the horizontal surface on which the press ram moves, providing a stable platform for your work.

Table of Key Components

| Component | Description |

|---|---|

| Frame and Base | Foundation of the shop press, providing stability and support. |

| Hydraulic System | Converts mechanical energy into hydraulic pressure for operation. |

| Press Ram | Moves up and down, exerting force on materials. |

| Die Blocks and Hold-Downs | Secure materials being worked on. |

| Control Panel | Interface between the operator and the shop press. |

| Workbench and Bed | Surfaces for performing metalworking tasks. |

Understanding the various parts of a 40 ton shop press is