Understanding Hydraulic Cylinder Size in Tons: A Comprehensive Guide

Hydraulic cylinders are essential components in various industries, from construction to automotive. They are responsible for converting hydraulic pressure into linear motion, making them crucial for lifting, pushing, and pulling heavy loads. One of the key specifications to consider when selecting a hydraulic cylinder is its size, often measured in tons. In this article, we will delve into the details of hydraulic cylinder size in tons, exploring its significance, calculation methods, and applications.

What is a Hydraulic Cylinder Size in Tons?

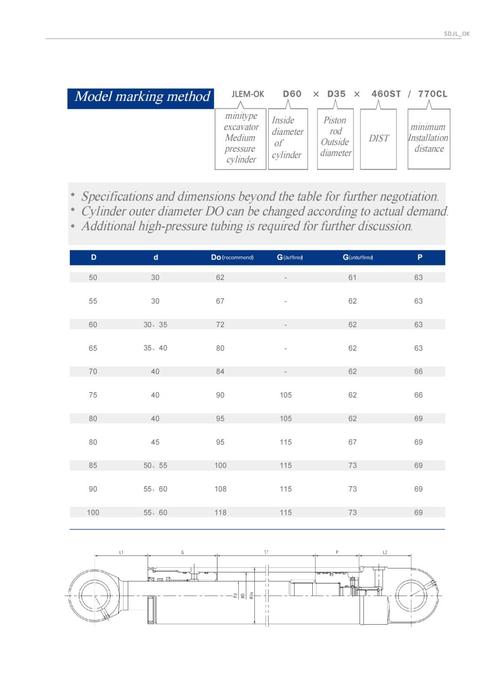

A hydraulic cylinder size in tons refers to the maximum load capacity of the cylinder. This capacity is determined by the cylinder’s bore diameter, rod diameter, and the material from which it is made. The size in tons is a convenient way to express the cylinder’s strength and suitability for specific applications.

Calculating Hydraulic Cylinder Size in Tons

Calculating the size of a hydraulic cylinder in tons involves several factors. Here’s a step-by-step guide to help you determine the appropriate cylinder size for your application:

-

Determine the required force: Calculate the force needed to move the load. This can be done by multiplying the load weight by the acceleration due to gravity (9.81 m/s虏).

-

Choose the appropriate pressure: Select the hydraulic system pressure that will be used to operate the cylinder. This is typically between 140 and 210 bar (2,020 to 3,045 psi) for most applications.

-

Calculate the cylinder bore diameter: Divide the required force by the system pressure. This will give you the cylinder bore area in square meters. To find the bore diameter, take the square root of the bore area and multiply it by 2.

-

Check the cylinder rod diameter: Ensure that the rod diameter is sufficient to handle the load. The rod diameter should be at least 10% of the bore diameter.

-

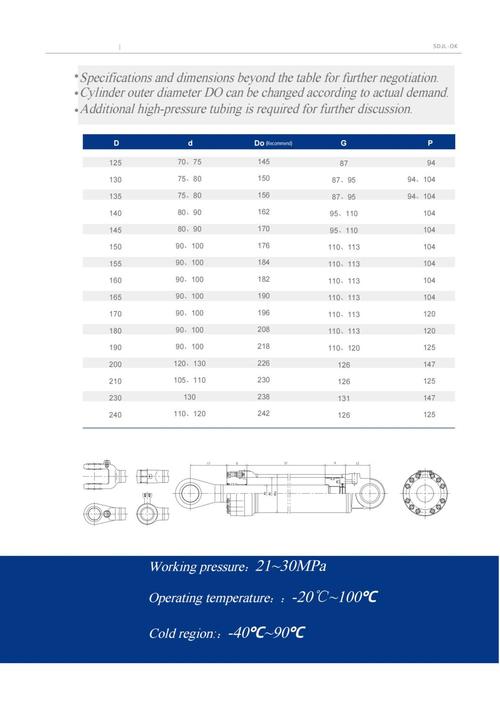

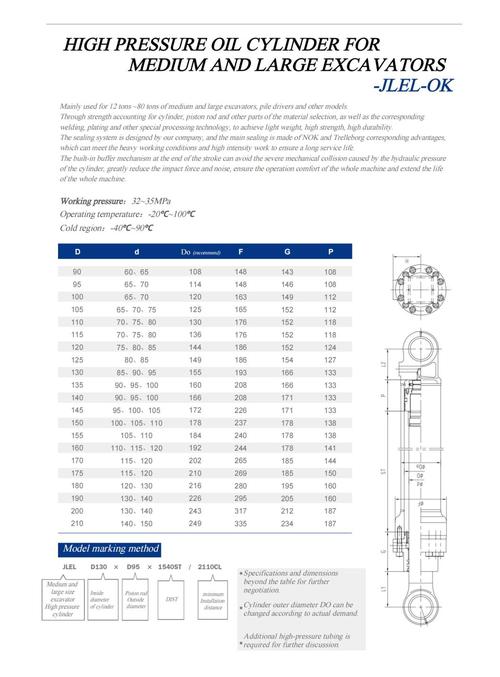

Consult the manufacturer’s data: Use the bore diameter and rod diameter to find the corresponding cylinder size in tons from the manufacturer’s catalog or technical specifications.

Here’s an example to illustrate the calculation process:

| Parameter | Value |

|---|---|

| Load weight (kg) | 1000 |

| System pressure (bar) | 200 |

| Required force (N) | 9.81 1000 = 9810 |

| Cylinder bore area (m虏) | 9810 / 200 = 49.05 |

| Cylinder bore diameter (mm) | 鈭?9.05 2 = 111.1 |

| Cylinder rod diameter (mm) | 10% of 111.1 = 11.11 |

Based on the calculations, a hydraulic cylinder with a bore diameter of 111.1 mm and a rod diameter of 11.11 mm would be suitable for this application.

Applications of Hydraulic Cylinders in Tons

Hydraulic cylinders are used in a wide range of applications across various industries. Here are some common examples:

-

Construction: Cylinders are used in cranes, excavators, and other heavy machinery to lift and move loads.

-

Automotive: Cylinders are used in vehicle suspensions, power steering systems, and other applications to provide linear motion.

-

Manufacturing: Cylinders are used in assembly lines, conveyors, and other automated systems to move and position parts.

-

Marine: Cylinders are used in shipboard cranes, winches, and other equipment to handle heavy loads.

-

Agriculture: Cylinders are used in tractors, combines, and other agricultural machinery to perform various tasks.