2 Ton Overhead Crane Hoist: A Comprehensive Guide

When it comes to lifting heavy loads in industrial settings, a 2 ton overhead crane hoist is an essential piece of equipment. This guide will delve into the various aspects of a 2 ton overhead crane hoist, including its design, features, applications, and maintenance. Whether you are a seasoned professional or a beginner in the field, this article will provide you with valuable insights into this crucial lifting device.

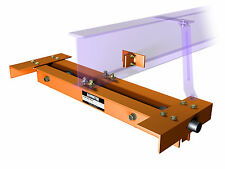

Design and Construction

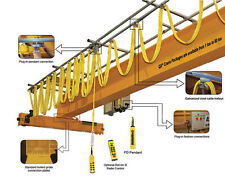

The design of a 2 ton overhead crane hoist is focused on providing maximum strength and durability. These hoists are typically constructed using high-quality steel materials, ensuring they can withstand the rigors of heavy-duty lifting operations. The following components make up the basic structure of a 2 ton overhead crane hoist:

- Hoist Frame: The frame is the backbone of the hoist, providing structural support and stability. It is usually made of heavy-duty steel and is designed to withstand the weight of the load and the forces exerted during lifting.

- Hoist Drum: The drum is where the wire rope is wound. It is designed to accommodate the required length of wire rope and is typically made of high-strength steel to ensure durability.

- Hoist Motor: The motor is responsible for driving the hoist and lifting the load. It is designed to provide the necessary power and torque for the specific lifting requirements.

- Control System: The control system allows the operator to control the hoist’s movement, including lifting, lowering, and stopping. It may include push buttons, joysticks, or other control devices.

Table 1: Key Components of a 2 Ton Overhead Crane Hoist

| Component | Description |

|---|---|

| Hoist Frame | Structural support and stability |

| Hoist Drum | Accommodates wire rope and provides winding capacity |

| Hoist Motor | Drives the hoist and lifts the load |

| Control System | Allows operator to control hoist movement |

Features and Specifications

2 ton overhead crane hoists come with a variety of features and specifications designed to meet the needs of different lifting applications. Some of the key features include:

- Load Capacity: As the name suggests, a 2 ton overhead crane hoist is designed to lift loads up to 2 tons (2,000 kg).

- Speed: These hoists can operate at various speeds, depending on the application. Standard speeds range from 5 to 20 meters per minute.

- Control Options: Modern hoists offer a range of control options, including push buttons, joysticks, and wireless remote controls.

- Safety Features: Many hoists come with safety features such as overload protection, emergency stop, and limit switches to prevent accidents and ensure operator safety.

Applications

2 ton overhead crane hoists are widely used in various industries, including manufacturing, construction, and logistics. Some common applications include:

- Manufacturing: Lifting heavy components, machinery, and raw materials during the production process.

- Construction: Moving materials and equipment to different locations on a construction site.

- Logistics: Loading and unloading heavy goods from trucks, trains, and ships.

Maintenance and Safety

Proper maintenance and safety practices are crucial for ensuring the longevity and reliability of a 2 ton overhead crane hoist. Here are some key points to consider:

- Regular Inspections: Conduct regular visual inspections of the hoist, including the frame, drum, motor, and control system, to identify any signs of wear or damage.

- Preventive Maintenance: Perform routine maintenance tasks, such as lubricating moving parts

About The Author