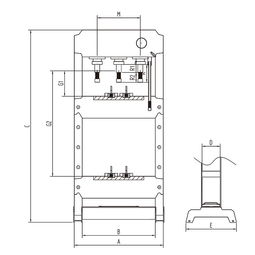

30 Ton Shop Press Manual: A Comprehensive Guide

Welcome to your ultimate guide on the 30 Ton Shop Press Manual. Whether you’re a seasoned mechanic or a DIY enthusiast, understanding the intricacies of your shop press is crucial for safe and efficient use. In this detailed guide, we’ll delve into the various aspects of the 30 Ton Shop Press, ensuring you’re well-equipped to handle any task that comes your way.

Understanding the Basics

The 30 Ton Shop Press is a powerful tool designed for heavy-duty applications in automotive, metalworking, and other industrial settings. With a lifting capacity of 30 tons, it can handle a wide range of tasks, from bending and straightening metal to installing bearings and other components.

Before diving into the specifics, it’s essential to familiarize yourself with the basic components of the shop press. These include the ram, which moves up and down, the bed, which supports the workpiece, and the hydraulic system, which provides the necessary force.

Setting Up Your Shop Press

Proper setup is crucial for safe and efficient operation. Here’s a step-by-step guide to help you get started:

- Position the shop press on a stable, level surface. Ensure it’s securely anchored to prevent movement during use.

- Check the hydraulic system for any leaks or damage. Top up the hydraulic fluid if necessary.

- Adjust the ram and bed to the desired position. Ensure they are aligned and properly secured.

- Inspect the press for any loose bolts or nuts. Tighten them as needed.

- Test the press by raising and lowering the ram a few times to ensure smooth operation.

Operating the Shop Press

Once your shop press is set up, it’s time to learn how to operate it safely and effectively:

- Always wear appropriate safety gear, such as gloves, safety glasses, and ear protection.

- Position the workpiece securely on the bed, ensuring it’s centered and properly supported.

- Adjust the ram to the desired height above the workpiece. Use the locking mechanism to secure the position.

- Engage the hydraulic system by turning on the pump and adjusting the pressure to the desired level.

- Lower the ram slowly and steadily, applying even pressure to the workpiece.

- Once the desired force is achieved, hold the ram in place for the required duration.

- Raise the ram and release the pressure before disengaging the hydraulic system.

Maintenance and Care

Regular maintenance is essential to keep your shop press in top condition. Here are some key maintenance tasks to consider:

- Check the hydraulic fluid regularly and top up if necessary. Replace the fluid every 1,000 hours of operation or as recommended by the manufacturer.

- Inspect the ram, bed, and other moving parts for signs of wear or damage. Replace worn-out components promptly.

- Ensure all bolts, nuts, and other fasteners are tight and secure.

- Keep the shop press clean and free of debris to prevent damage and ensure smooth operation.

Common Applications

The 30 Ton Shop Press is a versatile tool with a wide range of applications. Here are some common uses:

| Application | Description |

|---|---|

| Bending Metal | Use the shop press to bend metal sheets and rods to the desired angle and shape. |

| Straightening Metal | Apply pressure to straighten bent or warped metal components. |

| Installing Bearings | Use the shop press to install bearings into their housing with the necessary force. |

| Removing Bolts and Nuts | Apply pressure to remove stubborn bolts and nuts that are difficult to loosen by hand. |

Conclusion

By now, you should have a comprehensive understanding of the 30 Ton Shop Press and how to operate it safely and effectively. Remember to always prioritize safety and follow the manufacturer