Cost of 300mm Silicon Wafer Per Ton: A Detailed Overview

When it comes to the semiconductor industry, the cost of raw materials, such as silicon wafers, plays a crucial role in determining the overall production expenses. One of the most commonly used wafer sizes is the 300mm diameter, which is widely utilized in the manufacturing of various electronic devices. In this article, we will delve into the cost of a 300mm silicon wafer per ton, exploring various factors that influence its price and providing a comprehensive understanding of the market dynamics.

Market Overview

The global silicon wafer market has witnessed significant growth over the years, driven by the increasing demand for semiconductors in various industries, including consumer electronics, automotive, and healthcare. According to a report by Grand View Research, the global silicon wafer market size was valued at USD 14.5 billion in 2020 and is expected to reach USD 24.5 billion by 2027, registering a CAGR of 7.5% during the forecast period.

Factors Influencing the Cost of 300mm Silicon Wafers

Several factors contribute to the cost of a 300mm silicon wafer per ton. Let’s explore some of the key factors:

-

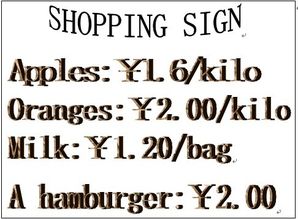

Raw Material Prices: The cost of silicon, which is the primary raw material for wafer production, significantly impacts the overall price. The price of silicon is influenced by factors such as supply and demand, geopolitical events, and mining operations.

-

Production Process: The manufacturing process of silicon wafers involves several steps, including crystal growth, wafer slicing, and surface preparation. The complexity and efficiency of these processes can affect the cost of production.

-

Quality and Specifications: The quality and specifications of the wafer, such as thickness, surface roughness, and defect density, play a crucial role in determining its price. Higher-quality wafers with better specifications tend to be more expensive.

-

Supply and Demand: The balance between supply and demand in the market can significantly impact the price of 300mm silicon wafers. A shortage of supply can lead to higher prices, while an excess of supply can result in lower prices.

-

Geopolitical Factors: Geopolitical events, such as trade disputes and sanctions, can affect the availability and cost of raw materials, thereby impacting the price of silicon wafers.

Market Trends

Several trends are shaping the market for 300mm silicon wafers:

-

Increased Demand for Advanced Nodes: The demand for advanced nodes, such as 7nm and 5nm, is expected to grow significantly in the coming years. This trend is driven by the increasing complexity of electronic devices and the need for higher performance and energy efficiency.

-

Expansion of Production Capacity: To meet the growing demand for 300mm silicon wafers, manufacturers are expanding their production capacity. This expansion is expected to lead to increased supply and potentially lower prices in the long run.

-

Shift Towards Monocrystalline Silicon: The shift from polycrystalline to monocrystalline silicon wafers is another trend in the market. Monocrystalline wafers offer better performance and are preferred for high-end applications.

Price Analysis

As of 2021, the average cost of a 300mm silicon wafer per ton ranges from USD 1,000 to USD 1,500, depending on the quality and specifications. However, prices can vary significantly based on the factors mentioned earlier. Below is a table showcasing the average price range for different quality levels of 300mm silicon wafers:

| Quality Level | Price Range (USD per ton) |

|---|---|

| Standard | USD 1,000 – USD 1,200 |

| High-Quality | USD 1,200 – USD 1,400 |

Ultra-High-Q

About The Author |